LXC series metering screw scale is a new type of electronic scale which organically combines the weighing technology principle of lever electronic belt scale with screw conveyor. It is mainly suitable for powdered form. Dynamic measurement for continuous conveying of bulk materials. A measuring device that controls the amount of feed. Especially applicable to the old factory in the process of renovation, space is small, unable to install other types of electronic metering equipment places. The product was recognized as a high-tech product by Jiangsu Provincial Science and Technology Department in 2004.

1.Scope of adaptation

LXC series metering screw scale is a new type of electronic scale which organically combines the weighing technology principle of lever electronic belt scale with screw conveyor. It is mainly suitable for powdered form. Dynamic measurement for continuous conveying of bulk materials. A measuring device that controls the amount of feed. Especially applicable to the old factory in the process of renovation, space is small, unable to install other types of electronic metering equipment places. The product was recognized as a high-tech product by Jiangsu Provincial Science and Technology Department in 2004.

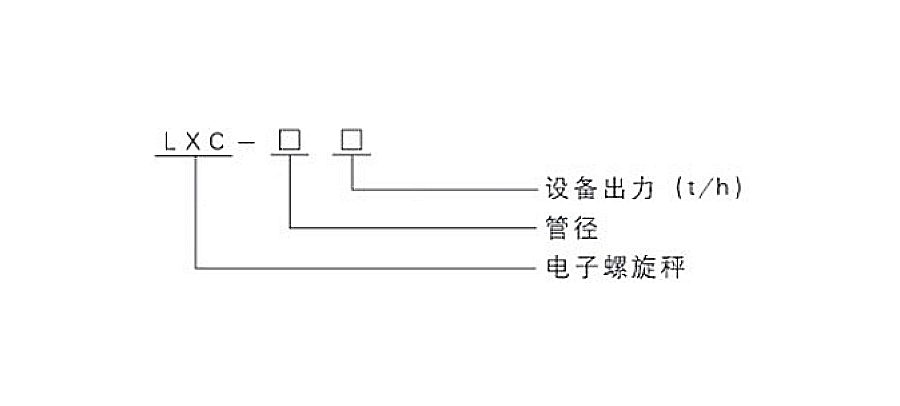

2.product model and meaning

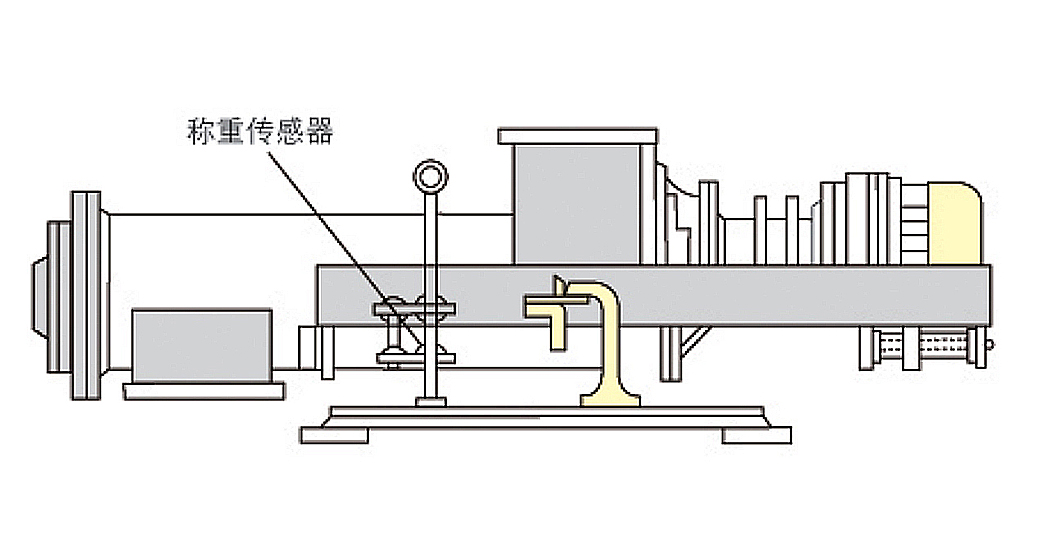

3The working principle

When the material is spiral conveying process, installed in the screw conveyor below the weight sensor detects the weight of the material and produces a voltage signal proportional to the load at the same time installed in the tail of the screw conveyor speed sensor detects the speed signal of the screw conveyor spindle, the two signals are sent into the weight integrator at the same time, after the integral calculation to obtain the instantaneous flow value and cumulative value.

4. system characteristics

Sealed structure, no dust publicity;

Dynamic metering is combined with spiral conveying to realize dynamic continuous metering.

Compact structure, small space, stable and reliable operation;

Automatic zero adjustment, automatic interval adjustment, all parameters are keytone input;

Using weight calibration, calibration is simple and convenient;

Photoelectric speed sensor, high precision, strong anti-interference ability;

With the impeller feeder can achieve fixed ratio fixed star batching, also can use the bin direct pressure type to achieve speed regulation batching.

5.Working principle diagram

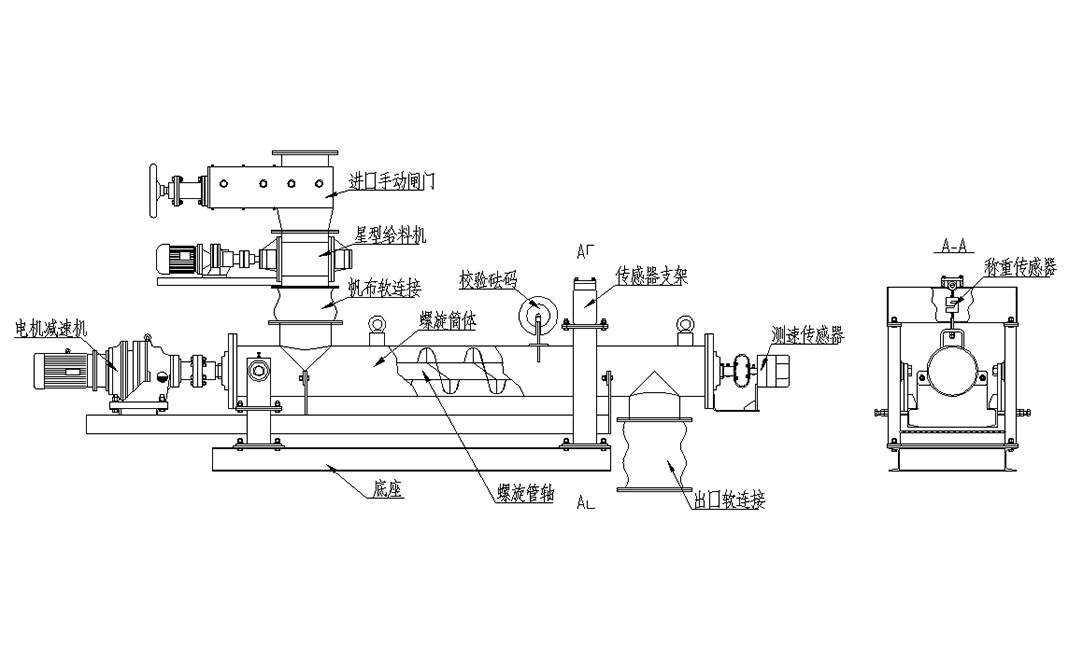

6. Screw weighing feeder equipment structure diagram