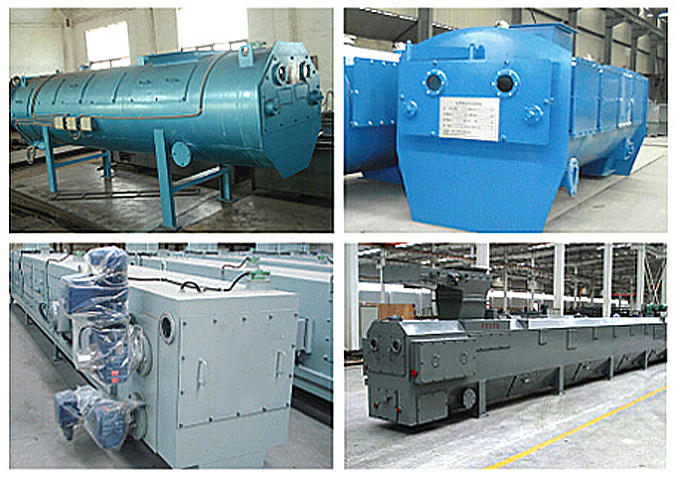

NJGC-30 series pressure type weighing coal feeder is the ideal equipment for coal-burning boiler and circulating vulcanized bed boiler in thermal power plant. With continuous coal feeding, dynamic metering, high precision, and can effectively match the running state of the boiler, automatic control of hot air channeling, so that the system operation more safe and reliable, for the site management, operation to provide accurate and reliable measurement data and control means, is to adapt to the operation process requirements of the advanced coal metering equipment.

1.Product parameters

NJGC-30 series pressure type weighing coal feeder is the ideal equipment for coal-burning boiler and circulating vulcanized bed boiler in thermal power plant. With continuous coal feeding, dynamic metering, high precision, and can effectively match the running state of the boiler, automatic control of hot air channeling, so that the system operation more safe and reliable, for the site management, operation to provide accurate and reliable measurement data and control means, is to adapt to the operation process requirements of the advanced coal metering equipment.

2.The main characteristics

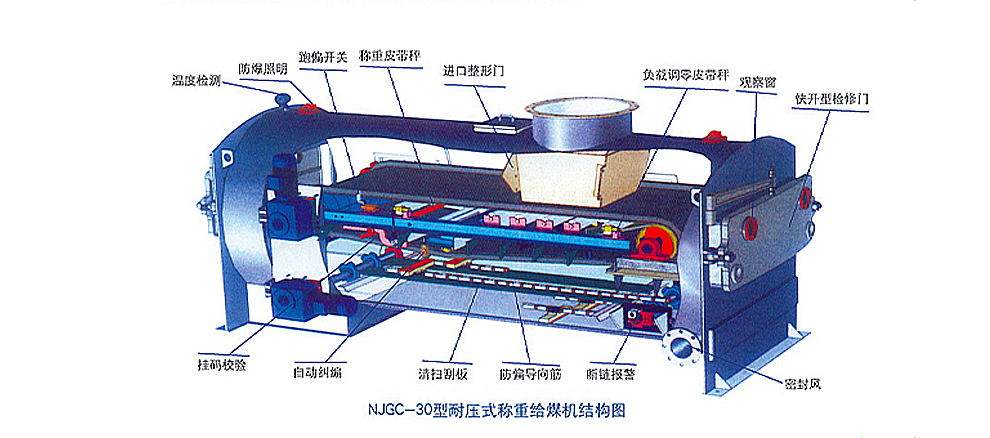

The strong closed shell of the coal feeder adopts the pressure resistant structure design, and the seal is tight. Can prevent air leakage and coal powder leakage, and can withstand the pressure of 0.35Mpa;

All outlet points are sealed with disc root to meet the pressure requirements of the equipment;

The front and rear access door adopts the card slot structure, and the inspection window adopts the blind hole structure to connect, effectively improving the sealing effect;

It is equipped with sealed air interface and adopts multi-point air outlet structure to improve sealing effect and effectively isolate hot air;

The coal feeder is of flat roller structure, and the belt is made of ring without joint with anti-deflection guide rib skirt flame retardant tape;

The surface of the active roller has a herringbone rubber layer, the driving force is strong, to prevent the belt deviation;

Driven roller adopts waist drum shape and self-cleaning structure, which can effectively prevent belt deviation and dry coal phenomenon;

The tail roller adopts spiral tensioning structure, which can be adjusted outside the body.

The return belt is equipped with a Mengli type automatic deviation correcting device to ensure the normal operation of the belt without deviation;

The main and driven rollers are supported by king bearings, and the lubrication is outside the shell;

Roller diameter 89mm, steel surface cylindrical, relative to the roller shaft radial runout small is conducive to measurement;

Coal feeder is equipped with automatic correction device, self-correcting belt deviation;

The coal feeder adopts heavy hammer scraping plate for cleaning the outer skin;

The bottom of the coal feeder adopts chain scraper conveyor to clean the fly ash.

Both ends of the coal feeder are provided with convenient maintenance end doors, with case window;

The coal feeder body is provided with a plurality of light bulbs in the non-stop idle condition can be easily replaced;

The inlet part is provided with a sliding adjusting type shaping door to ensure uniform material flow;

The measuring device adopts ICS-30 dual-sensor structure weighing bridge of Sanhuai Heavy Industry, which can effectively compensate the error caused by off-load.

Hanging code check device, can be checked outside the body;

The speed sensor adopts the tail installation to reduce the error caused by the slip of the leather, and increase the reliability of the speed sensor;

Sanhuai Heavy Industry coal feeder controller using 32 bit CPU, 20eA/D conversion data processing fast, effectively ensure the calculation accuracy. Have multiple numbers

Input function and communication function. It can communicate in a variety of ways; Drive motor connection mode; Direct coupling/chain drive/shaft mounting type.

3.Load zeroing technology

Automatic load zeroing technology is to complete automatic metering by installing a weighing bridge before and after the lower section of the mouth. After the loading section of the mouth, the weighing roller only weighs the tare weight, and before the lower section of the mouth, the weighing roller weighs the gross weight. The two weight values are sent into the controller at the same time to complete the automatic peeling in the conveying material section. The coal feeder load zeroing technology is controlled by Sanhuai Heavy Industry SHZIO5 special coal feeder controller. The controller can receive two signals of tare belt bang and gross belt scale, and the two signals are calculated on the integrated platform to realize the measurement and control of the coal feeder.

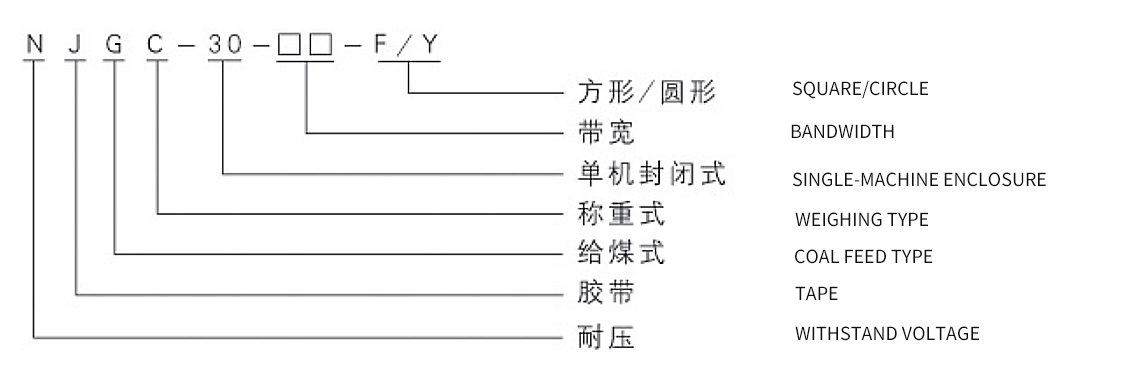

4. Product model and meaning

5.The working principle

When the coal enters the welder through the control gate the coal on the belt passes through the electronic belt type weighing area. High precision strain type weighing sensor mounted on weighing bridge. The weight of the coal is converted into a voltage signal and sent to the integrator. At the same time, the integrator receives the pulse signal from the photoelectric speed sensor mounted on the tail drum. By integrating the Meng basin signal and the velocity signal, the instantaneous moon discharge and the cumulative basin are obtained. The coal feeder is equipped with temperature sensors. The temperature is measured and compared with the set value. When the critical point is reached, the switch is output, and the signal is sent to the control system to quickly close the coal flow exit temperature isolation gate. So as to prevent hot air channeling purpose.

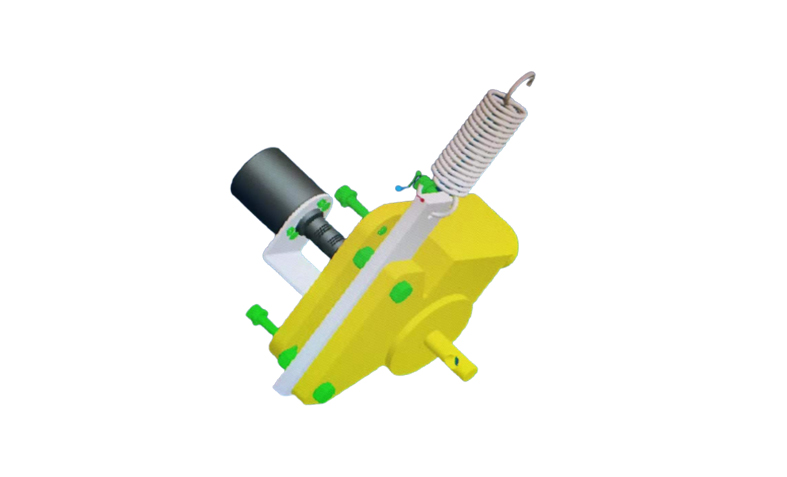

6. The speed sensor three-dimensional picture

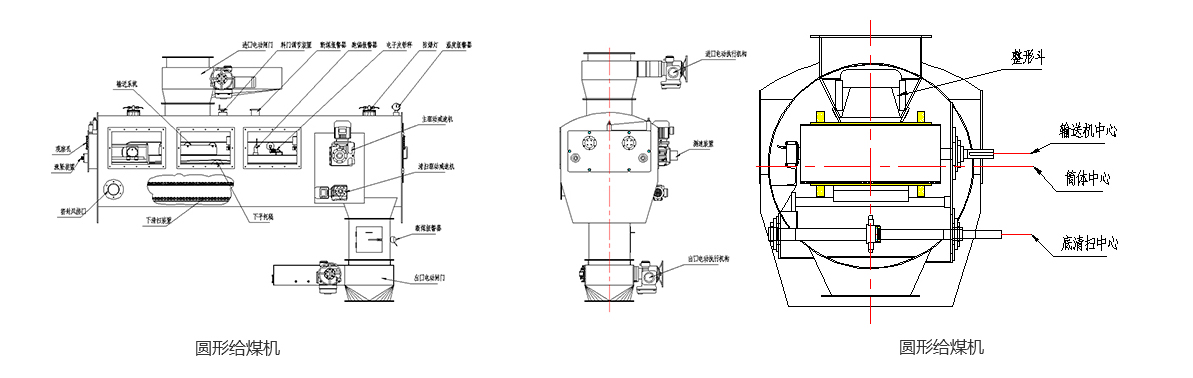

7.Product drawing

4.Product parameters

Machine pressure: 0.35MPa

Measurement accuracy: soil 0.5% or 0.25%

Conveying capacity: 1-1000t/h

Conveyor belt width: 500-1400mm

Center distance of inlet and outlet: >2000mm

Speed range: 0.01-0.5m/s

Total power: 1.1~10kw

Instrument output interface: RS-232/4854~20mA solid state relay pulse output

Alarm contact: temperature alarm blocking coal alarm belt deviation contact capacity 220VAC5A